Our Mission

Addressing the Unseen Crisis of Microplastic Pollution

In a time where every wash releases 700,000 microplastics into our oceans, Crustex acknowledges the urgency for change in the textile industry's environmental impact. We use chitosan found in crustacean shells to produce sustainable and 100% biodegradable fibres that release zero microplastics into our oceans

Drastically reduces the time by 520x taken to biodegrade compared to polyester composites

3x More resistant to tensile stress than polyester, lasting longer and perfect for clothing

100% less microplastics are released during washing and disposal of clothing.

⚪️ CRUSTEX

Better

for the

Planet,

Better

for

You.

Our Product

Our Approach to Sustainable Fibres

Our clothing isn't just made, it's meticulously crafted from the best of the ocean's offerings, ensuring each piece provides strength and sustainability far beyond the standard.

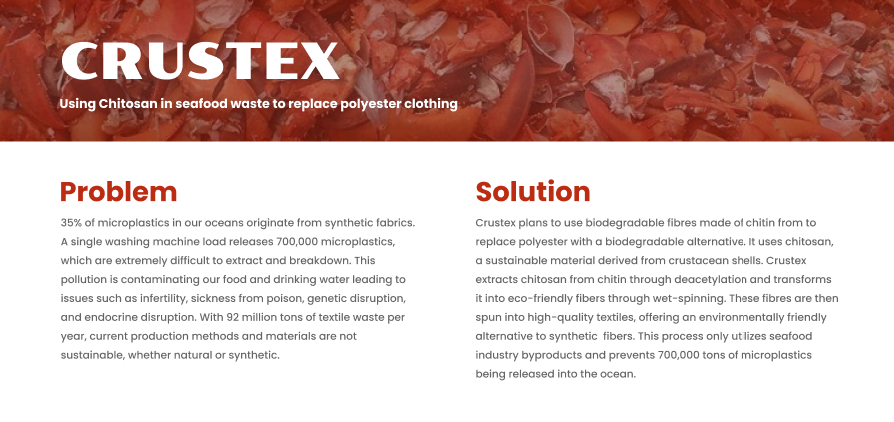

6-8 Million tonnes of crustacean shells are dumped into the ocean each year and they contain a valuable material: Chitin.

Crustec aims to use byproducts from the seafood industry to transform chitin into sustainable fibres that can be woven into everyday clothing.

This process has no environmental costs and creates a product that contains no microplastics.

The Fabrication Process

1. Chitin Extraction

6 to 8 Million metric tons of seafood waste are generated each year and either dumped into the ocean or sent to landfills. However, the exoskeleton of these crustaceans contain the worlds second most abundant polysaccharide: Chitin. This is extracted by 1st. Removing calcium phosphate using a strong acid in the vessel and 2. eliminate any proteins adhering to the chitin via an alkaline (strong base) bath.

Read more →

2. Chitin to Chitosan Conversion

Deacetylation is the critical step that transforms chitin into chitosan. During this process, acetyl groups (CH₃–CO) are removed by treating them with a 50% w/w NaOH solution in an ultrasonic deacetylation reactor and heating system to elevated temperatures. The result is a powder-like substance called Chitosan.

Read more →

Using Seafood Waste to Eliminate Microplastics

Want more detail? Learn more about Crustex using these links.

Explore the most common questions about Crustex's sustainable practices, the benefits of chitosan, and our unwavering commitment to a greener future.

Answers for an Eco-Smart World

CRUSTEX

Are you ready to join the Crustex movement? Make the choice that aligns with your values and heralds a new chapter in sustainable fashion, one garment at a time.